Geppetto® D2O Custom Expansion Boards Available for MitySOM®-335x

Geppetto® D2O Custom Expansion Boards Available for MitySOM®-335x

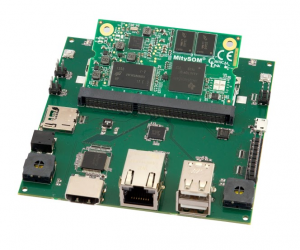

Gumstix®, Inc., the leader in design-to-order embedded systems, today announced a partnership with Critical Link, LLC to provide support for Critical Link MitySOM-335x COMs in Geppetto® Design-to-Order (D2O) platform created by Gumstix engineers. Using Geppetto D2O, customers can rapidly design and manufacture small form-factor boards custom tailored for industrial applications that require the versatility of the MitySOM®-335x powered by the Texas Instruments Sitara™ AM335x family of processors.

Critical Link specializes in building both affordable and powerful system-on-modules (SOMs), also known as COMs, for scientific and industrial applications. With the inclusion of the Geppetto D2O MitySOM-335x Connector and Gumstix MitySOM-335x development board into the Geppetto D2O platform, Critical Link customers now have two paths to create custom expansion boards to actualize the audio, visual, networking and robotic potential of the MitySOM-335x.

“In today’s world, the ability to get to market faster than the competition can make or break the success of a product,” says Tom Catalino, Vice President of Sales and founding Partner at Critical Link. “Our SOMs have been helping customers accelerate their time to market while cutting development costs for over a decade, and now the Gumstix partnership puts Geppetto D2O, a simple and powerful online design tool, in the hands of our customers, further maximizing their potential for success.”

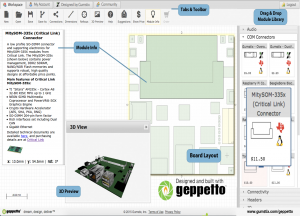

Using Geppetto D2O within their browser, customers can clone and drop the Gumstix MitySOM-335x dev board into the Geppetto D2O workspace to jumpstart their design or custom build an expansion board for the MitySOM-335x from scratch utilizing the simple drag and drop interface. The Gumstix MitySOM-335x expansion board is especially suited for video and audio applications incorporating an audio codec for left and right speakers, an HDMI port for audio and visual displays and SPI, UART, I2C and 20-pin Male headers.

“Critical Link customers can now evaluate development boards from Gumstix that are also available for rapid customization in Geppetto.” says Gordon Kruberg, Gumstix CEO, “Geppetto provides them a path to manufacturing the embedded product in one online order, deliverable in three weeks.”

Once customers are satisfied with their expansion board designs in Geppetto D2O, engineers at Gumstix will test and validate the board design, manufacture and ship the production ready board 15 days from order; reducing both the production and development time for the customer. All Gumstix products and quantity discounts are available at www.gumstix.com.

About Gumstix, Inc.

As a global leader in design-to-order hardware and manufacturing solutions, Gumstix® gives its customers the power to solve their electronic design challenges with Geppetto® D2O — the online design-to-order system– and a broad portfolio of small computers and embedded boards. In addition to engineers and industrial designers, Gumstix helps students, educators, and makers unlock their creative ideas to bring them to market. Since pioneering the concept of an extremely small computer-on-module (COM) with a full implementation of Linux in 2003, the company has grown to support over 20,000 diverse customers. Our systems have launched some of the world’s coolest products – from phones to drones – on commercial, university, and hobbyist workbenches in over 45 countries. For more information, visit www.gumstix.com

About Critical Link

Syracuse, N.Y.-based Critical Link (www.criticallink.com) is an embedded systems engineering firm, offering a broad range of highly customizable, small form factor system-on-modules (SOMs) for highly integrated, embedded systems for industrial, medical, scientific, and defense applications. Critical Link’s end-to-end product engineering offerings include design, development, and production services. Critical Link is a Platinum Member of the Texas Instruments Design Network and is ISO 9001:2008 and ISO 14001 Registered by SRI Quality System Registrar.

About the Texas Instruments Design Network

Gumstix, Inc. and Critical Link are members of the TI Design Network, a premier group of independent, well-established companies that offer products and system-level design and manufacturing services complementing TI’s semiconductors to a worldwide customer base to accelerate product innovation and time-to-market. Network members provide product design, hardware and software system integration, turnkey product design, RF and processor system modules, reference platforms, software development, proof-of-concept design, feasibility studies, research, certification compliance, prototyping, manufacturing, and product life cycle management. For more information about the TI Design Network, please visit http://www.ti.com/designnetwork.

The MitySOM-335x Maker Transition Kit enables maker-pros to convert prototypes based on the BeagleBone Black with TI’s AM335x ARM processor to production-suitable designs leveraging Critical Link’s proven MitySOM-335x platform. The kit is designed to minimize changes when transitioning from the BeagleBone Black, and in many cases is a drop-in replacement. Interested developers can visit Critical Link’s engineering site to review design documentation and engage with our engineering team.

The MitySOM-335x Maker Transition Kit enables maker-pros to convert prototypes based on the BeagleBone Black with TI’s AM335x ARM processor to production-suitable designs leveraging Critical Link’s proven MitySOM-335x platform. The kit is designed to minimize changes when transitioning from the BeagleBone Black, and in many cases is a drop-in replacement. Interested developers can visit Critical Link’s engineering site to review design documentation and engage with our engineering team. Critical Link will also be featuring an embedded vision demo using our MityDSP-L138F, a system on module based on TI’s OMAP-L138 with Spartan FPGA. Originally introduced in 2010, the MitySOM-L138F continues to be selected for new applications in unmanned systems, utilities management, networking & communication systems, factory automation, and test & measurement, among many others.

Critical Link will also be featuring an embedded vision demo using our MityDSP-L138F, a system on module based on TI’s OMAP-L138 with Spartan FPGA. Originally introduced in 2010, the MitySOM-L138F continues to be selected for new applications in unmanned systems, utilities management, networking & communication systems, factory automation, and test & measurement, among many others.