At one point or another, most of us – in search of a tasty tomato in the dead of winter, or a head of Bibb lettuce for a salad – have picked up some hydroponic produce at the grocery store. I take it that there’s some back and forth about whether hydroponically-grown fruit and vegetables are as nutritious as the soil-grown versions. But whatever side someone comes down to in that debate, hydroponics seems to bring with it a number of important environmental and other benefits:

- It uses less water than traditional agriculture

- It has a far shorter growing season

- Growing doesn’t require the use of herbicides and pesticides

- Food can be grown year-round, making fresh product more readily available

- For the size of the footprint, the yield is greater than with land-based growing

- Food can be produced locally, saving on transportation costs

Like much of today’s agriculture, hydroponics relies on technology. (We’ve posted about the use of technology in agriculture in the past in The Internet of Tomatoes and in Robotic Milking (Yes, Technology Is Everywhere).) One company that’s involved in hydroponics – and which makes greenhouses that are highly-evolved solution from the technology perspective – is GotProduce?, which focuses primarily on developing countries, especially those that are most susceptible to drought.

GotProduce? systems are “smart”, full of all sorts of technology to help ensure that growers succeed. For one thing, t

hey come pre-programmed for the specific location and crops, taking guesswork and trial and error out of the farming equation.

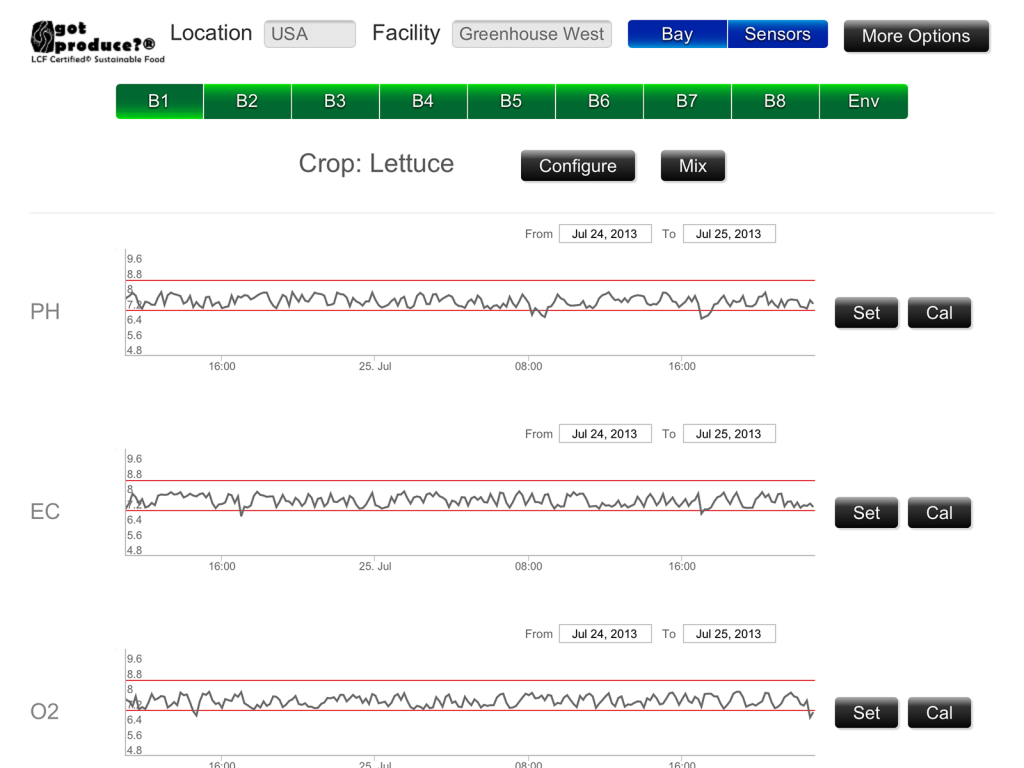

Each greenhouse is equipped with a Linux controller running on its own LAN. Wireless sensors – some of which are DSP-based – monitor all the environmental factors: pH, EC, temp, water level, light, Rh… The control interface displays data on all the parameters being monitored, controls irrigation, fertigation injectors (fertilizing through the watering system), pumps, and all the sensors. It also handles alerts/alarms, maintenance reminders, etc.

The data sync back to the cloud via ISP modem. There the greenhouse data are stored, enabling GotProduce? to check on greenhouse conditions remotely. Interestingly, GotProduce will be moving away from stationary sensors entirely and moving towards the use of drones to take readings from all points in the greenhouse. Because the greenhouses are enclosed, there’s no issue with regulatory policies that govern the use of drones flying outdoors.

Always interesting to learn about how technology is being deployed in so many ways we may not think about on a day-to-day basis. Next time I pick up a hydroponically grown tomato, I’ll have new respect for it!